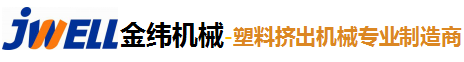

GAG高光装饰膜生产线

更新:2022/11/23 10:34:42 点击:

- 产品品牌 金纬机械

- 产品型号 JWELL-2022

- 产品描述

金纬机械推出新一代GAG装饰膜生产线,具有低能耗、效率高的优点,目前可提供技术成熟的同向双螺杆挤出生产线和单螺杆挤出生产 线。 Jwell Machinery has launched a new...

产品介绍

GAG高光装饰膜生产线

GAG High Gloss Decorative Sheet Production Line

金纬机械推出新一代GAG装饰膜生产线,具有低能耗、效率高的优点,目前可提供技术成熟的同向双螺杆挤出生产线和单螺杆挤出生产

线。

Jwell Machinery has launched a new generation of GAG decorative film production line, which has the advantages of low

energy consumption and high efficiency. Currently, it can provide mature co-rotating twin-screw extrusion production lines and

single-screw extrusion production lines.

使用物料 Use Material:APET、PETG

片材类型 Sheet Type:单面磨砂片、高光透明片、颜色磨砂片、高光颜色片、哑光薄膜、透明薄膜;

Single-sided frosted film, high-gloss transparent film, color frosted film, high-gloss color film, matte film, transparent film.

片材特点 Sheet Features:

GAG装饰膜适用于家具表面的环保平贴用膜,产品使用绿色环保材料,具有出色的耐磨、耐污、耐黄变等性能,使家具表面呈现出各种时

尚靓丽的视觉效果。

GAG decorative film is suitable for environmental protection flat film on furniture surface. The product uses green environmental

protection material, which has excellent wear resistance, stain resistance, yellowing resistance and other properties, so that

the furniture surface presents various fashionable and beautiful visual effects.

设备特点 Features:

◎采用全新螺杆组合形式,使物料塑化充分、色母分散均匀,确保了产品良好的韧性和色泽均匀度;

◎采用高效三级抽真空系统,有效去除熔体中水份及单分子挥发物,提升制品性能;

◎采用超镜面合金钢薄壁辊筒,即满足制品的快速冷却定型,又能提升装饰膜表面质量;

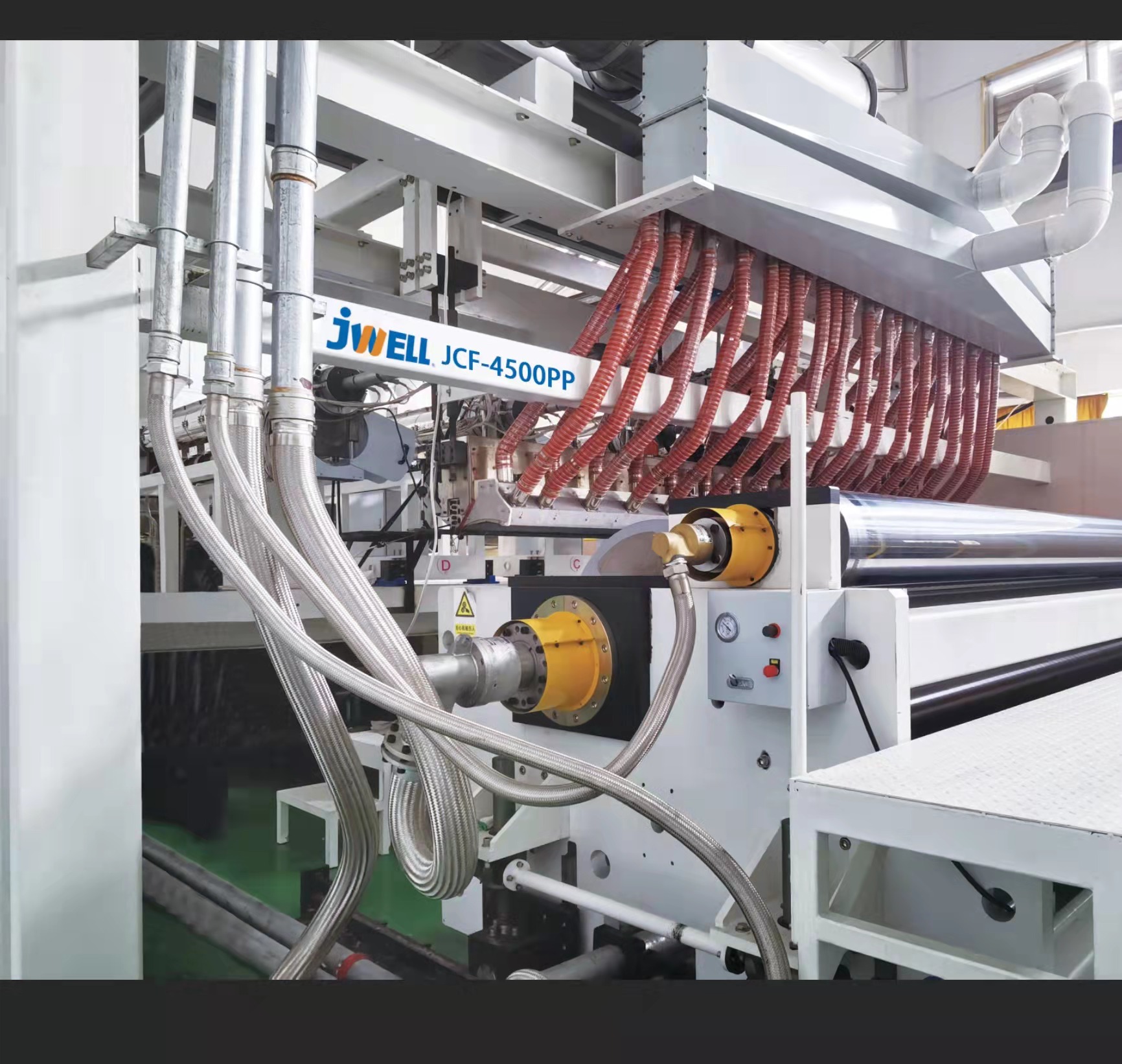

◎采用自动翻转双工位收卷机,实现自动裁切、自动上卷、确保宽幅片材生产中的稳定生产,收卷轴采用伺服电机驱动,可实现多段张力

或锥度收卷,确保收卷卷材端面整齐,张力稳定,并能够满足3英寸和6英寸气涨轴的切换;

◎整线采用一流变频控制和伺服控制,实现高效、高精度控制,可通过人机界面HMI,实现整线参数预览、参数调整、一键联动,使操作

更加方便;

◎24小时网络远程服务,实现故障诊断、错误分析及故障排除,减少了调试和生产停机时间。

◎Using a new screw combination form, the material is fully plasticized and the color masterbatch is evenly dispersed, ensuring

good toughness and color uniformity of the product;

◎Adopt high-efficiency three-stage vacuum system to effectively remove water and monomolecular volatiles in the melt and

improve product performance;

◎The ultra-mirror alloy steel thin-walled roller is used, which not only satisfies the rapid cooling and shaping of the product,

but also improves the surface quality of the decorative film;

◎The automatic turning double-station winder is adopted to realize automatic cutting, automatic winding, and ensure stable

production in the production of wide sheets. The winding shaft is driven by a servo motor, which can realize multi-stage tension

or taper winding to ensure the The end face of the coil is neat, the tension is stable, and it can meet the switching of 3-inch and

6-inch air shafts;

◎The whole line adopts first-class frequency conversion control and servo control to realize high-efficiency and high-precision

control. Through the human-machine interface HMI, the whole line parameter preview, parameter adjustment and one-key

linkage can be realized, which makes the operation more convenient;

◎24-hour network remote service to realize fault diagnosis, error analysis and troubleshooting, reducing debugging and

production downtime.

地

更多产品